STEEL BARREL

STEEL BARREL PRODUCTION LINE

- 10PCS/MINUTE HIGH SPEED STEEL BARREL PRODUCTION LINE

- 7PCS/MINUTE HIGH SPEED STEEL BARREL PRODUCTION LINE

- 5PCS/MINUTE MIDDLE SPEED STEEL BARREL PRODUCTION LINE

- 1PCS/MINUTE LOW SPEED STEEL BARREL MACHINERY

Technical Problems and Solutions of Steel Barrel Production Line

First, the steel drums powered welding workshop Interference Problems

In steel drums production workshop , the use of multi- spot welding, projection welding and seam welding equipment , there are often power fluctuations and the impact of the workshop welding quality problems that may often appear protective tripping , power outages and other problems, sometimes other cooperage equipment is also subject to varying degrees of interference , seriously affecting the normal production. These problems arise , are generally used as a simple power plant cosine (cosφ) result of the compensation .

1 , steel drums powered welding workshop causes interference problems

In steel drums production workshop , the use of multi- spot welding, projection welding and seam welding equipment , there are often power fluctuations and the impact of the workshop welding quality problems that may often appear protective tripping , power outages and other problems, sometimes other cooperage equipment is also subject to varying degrees of interference , seriously affecting the normal production. These problems arise , are generally used as a simple power plant cosine (cosφ) result of the compensation .

2 , steel drums powered welding shop cause interference problems

ERW steel drum production workshop concentrated supply and management problems are not common problems with the supply of electricity . Drums welding shop has its special electrical loads regularity .

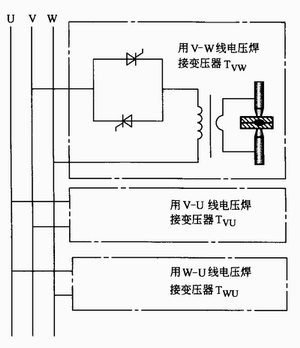

General drums are used in welding equipment welding power thyristor AC voltage . The welding power supply according to the load balancing principles are respectively connected to three-phase power cable plant , as shown , U, V, W phase cable is the power plant substation transformer secondary side (380V) output.

Cooperage shop multiple welding equipment connected to the grid

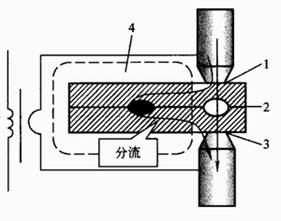

Each welding power source , includes a welding transformer , and all electrical loads including transformers , including all belong to the inductive load . Since the total work drums also has a certain resistance ( resistance welding the workpiece shown in Figure composition , mainly the workpiece contact resistance and inductance of the secondary loop ) , so the resistance of the workpiece into account the nature of the load resistance welding as a barrier to emotional .

ERW constitute inductive load

That should be noted that the inductance of inductive load resistance welding resistance portion , in addition to including a welding transformer , the secondary side of the self-inductance , and a , the mutual inductance between the secondary side , there is inserted into the workpiece due to the secondary the inside of the side loop inductance caused .

Welding process, with the workpiece extends into the inside of the secondary circuit changes and the weld nugget shunt resistance of such blocking resistance welding inductive nature of the load in and added to the dynamic properties.

Since the resistive inductive load resistance welding complexity , taking into account the main welding power supply circuit , the use of high-power thyristor AC switches , the result causing power supply - dynamic resistive inductive load, multi-channel thyristor phase control adjustment pressure system to the following features:

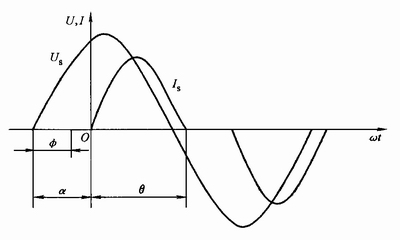

(A) the welding current itself is "off" ( not connected ) of the non-sinusoidal waveforms ( as shown).

(B) changes in the load with power factor ( angle ) . Resistance welding machine welding transformer integrated , the power factor ( angle) of the approximate range of : cosφ = 0.9 ~ 0.6, φ = 9 ° ~ 70 °. This shows that when the power to the load resistance welding current total , there are 10% to 40 % of the reactive current. Reactive current, welding shop drums means low power factor , which requires on the grid for power factor compensation , but also increase the power supply ( power transformer ) capacity (kVA number ) .

From the perspective of power supply , the power supply drums welding workshop use of the capacity there is a considerable waste; welding process from the perspective of welding current is not large enough , there is no qualified welding mass ( nugget ) . This " wasted capacity " and " Ning Fei shelf " of electricity supply and demand in the steel drums welding shop is very prominent.

Welding power supply circuit waveforms Thyristor

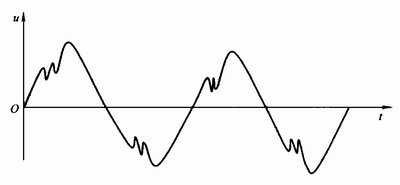

(C) As ERW inductive resistive load , causing power thyristor AC voltage regulator circuit ( ie, the main welding power supply circuit ) , will produce a transient inrush current , its value is purely resistive loads up quite a few times or even ten times, with the welding workshop drums resistive inductive load is large , centralized applications , the total "effect" is the sine -shaped power voltage " twisted " into the grid as shown in waveform distortion .

Drums grid waveform distortion resistance welding workshop

This distortion of the grid voltage waveform on sharing power transformer power supply , welding supply , welding power control appliances, levels of control devices can cause strong electromagnetic interference.

From the perspective of each welding power , welding, electromagnetic interference generated by it will be " disturbing neighbors " ; And it is also affected by " neighbor disturbed ." Its overall situation is: often unexplained disorder welding procedures , welding current is not normal , and even welding equipment also sometimes " gaffe ."

3, to solve the interference problem drums welding shop supply measures

The main problem to solve the above power management measures are:

( A ) to install on each welding power " interference " circuits.

Each welding machine controller should have the load power factor (cosφ) random automatic detection and current network voltage fluctuation compensation function and the more advanced controllers.

ERW welding current controller shall provide automatic compensation mode, that constant current ACC, and grid voltage automatic compensation mode , ie constant voltage AVC, for the operator according to the workpiece according to the grid welding process requirements Ah specific circumstances , to choose a different mode.

( 2 ) in the workshop of the power supply management computer, install " electric resistance welding performance management software package" , and its main function is to limit both the " welding energized interrupt request " in the number of resistance welding machine , so as not to overload the power grid .

When a serious shortage of power supply , the welding device does not work, close to the normal power supply voltage (360V ~ 410V); When welding equipment work, the current increases rapidly cause the controller supply voltage down to about 200V or even lower , especially in multi- Taiwan high-power welding machine while connected to a power supply and phase simultaneously, there will be a serious shortage of welding parts intensity ( reduced quality of welding ) , also causing the controller work instability.When the supply voltage fluctuations in a wide range , will inevitably lead to welding power and welding time controller unstable and inaccurate .

When welding equipment welding parameters to adjust properly, such as welding time adjustment is too long or too short , adjust the welding energy too large or too small , will cause workpiece welding performance can not be guaranteed . To this end, advanced power management software workshop , welding equipment includes a power management software , which controls the idea is: using a highly sensitive voltage monitor single-phase , respectively, to monitor various power lines . When the monitor to which a certain line voltage drops below the set value, the interrupt request to the master PLC . Interrupt routine first checks to what extent the line voltage is low , and then dealt with separately. Interrupt program will follow the process to the extent permitted , to hang on the line welder scheduled order , through field bus control device PLC, let the command on the line powered welding welding equipment in chronological order , so that each a welding device has sufficient operating current.

Second, the steel drum coating drying technology and process issues

1 , far infrared radiation heating heating is not an ordinary convection heating or conduction heating .

Heat is a form of energy there is , the temperature is a measure of heat energy .Between substances of different temperatures , according to the principle of conservation of energy for heat exchange - heat . Heat transfer is a complex process, but the result is always the heat transfer from the higher temperature heat to the lower temperature of the object of the object . People of this nature is often used for heating of objects . Actual heating methods are varied, but the basic method for heat exchange purposes , there are only three kinds - heat conduction , convection and radiation heat transfer .

Means relying on heat conduction between the different objects or the same object within the direct contact between the parts of the energy propagation occurs . Solid surface convection heat transfer is in direct contact with the gas or liquid between each other when the heat transfer process , which relies on the fluid flow relative position of the fluid molecules and mixed to achieve the purpose of heat transfer , the actual conduction and convection of fluid in the process act simultaneously . Radiation heat transfer between objects is different energy carriers of electromagnetic waves through the transfer process . Both conduction and convection heat transfer to the solid or solid and the fluid between the case of contact with each other can be carried out , it would have to be carried out with the heat exchange medium . The radiation heat transfer between objects , without direct contact , even high vacuum , very far away objects can be carried out between . Far infrared heating technology that is part of a radiant heating .

Conventional electric heating or gas heating fuel , heat conduction and convection are heated by hot air convection heat from the heat source to the paint on the surface , and then through the inner layer conductive potential temperature. In this way , the intermediate long process , heat loss is large , so the heating time is long and inefficient . As the paint surface temperature , is not conducive to the diffusion of organic solvent .Hot air heating heat unevenly , will produce orange peel , pinholes , bubbles , etc. affect the quality .

Far infrared radiation heating , heat rays toward the speed of light by the paint surface of the radiator , not the media center , the energy loss . Also, because there is a certain penetration of electromagnetic waves , so the radiation can penetrate into the paint , the table at the same temperature , uniform heating , the film quality is better.

2, on the furnace temperature and ventilation problems

Heating drums , the drums mostly in the process of heating with an organic solvent removal of volatiles on the far infrared rays have a strong absorption effect, will greatly reduce the heating efficiency . Volatile organic compounds furnace heated too much will affect the quality , when the concentration exceeds the limit there is a risk of ignition , so the ventilation system should be set emissions of harmful gases. Appropriate to increase the furnace gas flow can also help organic solvent molecules escape from the surface of steel drums and reduce oven temperature down .

Because heating is by far infrared radiation heating , increase air flow furnace heating has little effect on the drums , because the furnace organic solvents can be swapped out in time to accelerate the dry paint film . Imagine when the internal organic solvents due to poor ventilation can not be swapped out , it is equivalent to the steamer steamed bun , steamed bun high temperature and then it will not dry !

3 , when the far-infrared drying oven drying effect is not good ?

( 1 ) far infrared heating element is too long , has lost the function of far infrared radiation heating (generally far infrared heating elements to be replaced every three years ) , only by an electric air convection heating furnace , reducing the thermal efficiency.

( 2 ) As far infrared furnace heating element failure due to obsolescence , and only raise the temperature of the drying furnace atmosphere . In order to maintain the temperature of the atmosphere , reducing the ventilation , causing the furnace produced a steamer effect , organic solvents could not row , the film could not do naturally .

( 3 ) infrared furnace section element is damaged, causing less heat , the drums reduce the surface temperature , easy to dry the paint .

( 4 ) ventilation system failure , ventilation negative, so that the furnace high concentration of organic solvent , the solvent is not easy to escape the surface of drums , paint drying difficult.